In this guide we discuss the different types of flexible heaters available and compare their typical specifications, applications, and merits of each type.

If you still have a question, then please ask us via contact form or give us a call on +44(0)1865400514.

Contents:

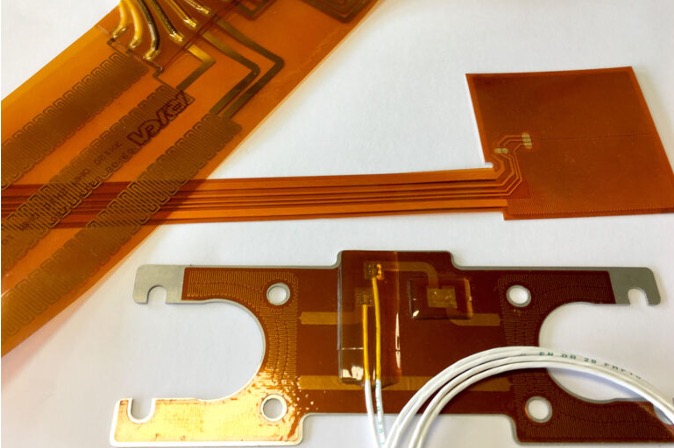

1. Basic construction of flexible heaters

2. Flexible heater selection guide

If you still have a question, then please ask us via contact form or give us a call on +44(0)1865400514.

Contents:

1. Basic construction of flexible heaters

2. Flexible heater selection guide