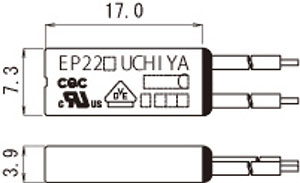

EP2 Thermal Protectors are world’s only Dual Spring Mechanism and have stronger contact spring meaning higher vibration and impact durability. Their bigger non-trip current acceptable by changing inner live parts material. Other advantages of EP Thermal Protectors are their overload and overheat protection for Direct Current devices (please see model JP for AC devices) as well as EPs are suitable for quick charger battery pack.

EP2 and EP4 Thermal Protectors

- Home

- Products

- Thermal Protectors and Cut-offs

- EP2 and EP4 Thermal Protectors

Those are used in a wide range of applications such as:

- Power tools

- Battery Packs

- Battery Chargers

- DC Small Motor

Technical details:

- Operating Temperature: 55-130ºC (5ºC step)

- Tolerance: ±5ºC; ±7 ºC; ±10 ºC

- Differential: 40 ± 15K (standard)

- Breaking Capacity: - 13A 26V DC 6000 cycle (resistive)

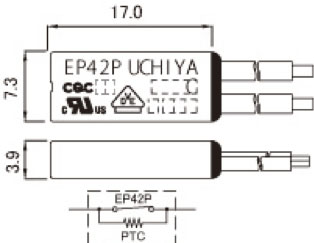

EP42P Thermal Protectors have many advantages including the following:

- Safer OFF Self-holding type reset

- Reliable PTC Heater (2.5k ohm or 10k ohm

- Complies with EN standard (keep OFF at -20ºC)

- Complies with UL standard (keep OFF at 0ºC 125V/250V)

Used in applications:

- Overload protection

- Overheat protection

- Small motors

- Lighting fixtures

- Power tools

- Garden Tools

- Vending Machines

- Industrial Machinery

Specifications:

- Operating Temperature: 60-140ºC (5ºC step)

- Tolerance: ±5ºC; ±7 ºC; ±10 ºC

- Reset: Non-automatic reset

- Breaking Capacity:

- 8A 125V AC 3000 cycle (resistive)

- 5A 250V AC 3000 cycle (resistive)

Visit our downloads page to view technical characteristics or contact our technical sales department for more information, prices or with your specifications.

Also, you can reach us on +44 (0) 1865400514

Also, you can reach us on +44 (0) 1865400514